You've Experienced This Before

PartDNA™ Traceability

Complete Traceability, Zero Guesswork

Every part we manufacture carries a digital fingerprint. One scan gives you complete history and instant access. When your customer asks 'where did this part come from?' — you'll have the answer in seconds.

Trusted by Industry Leaders

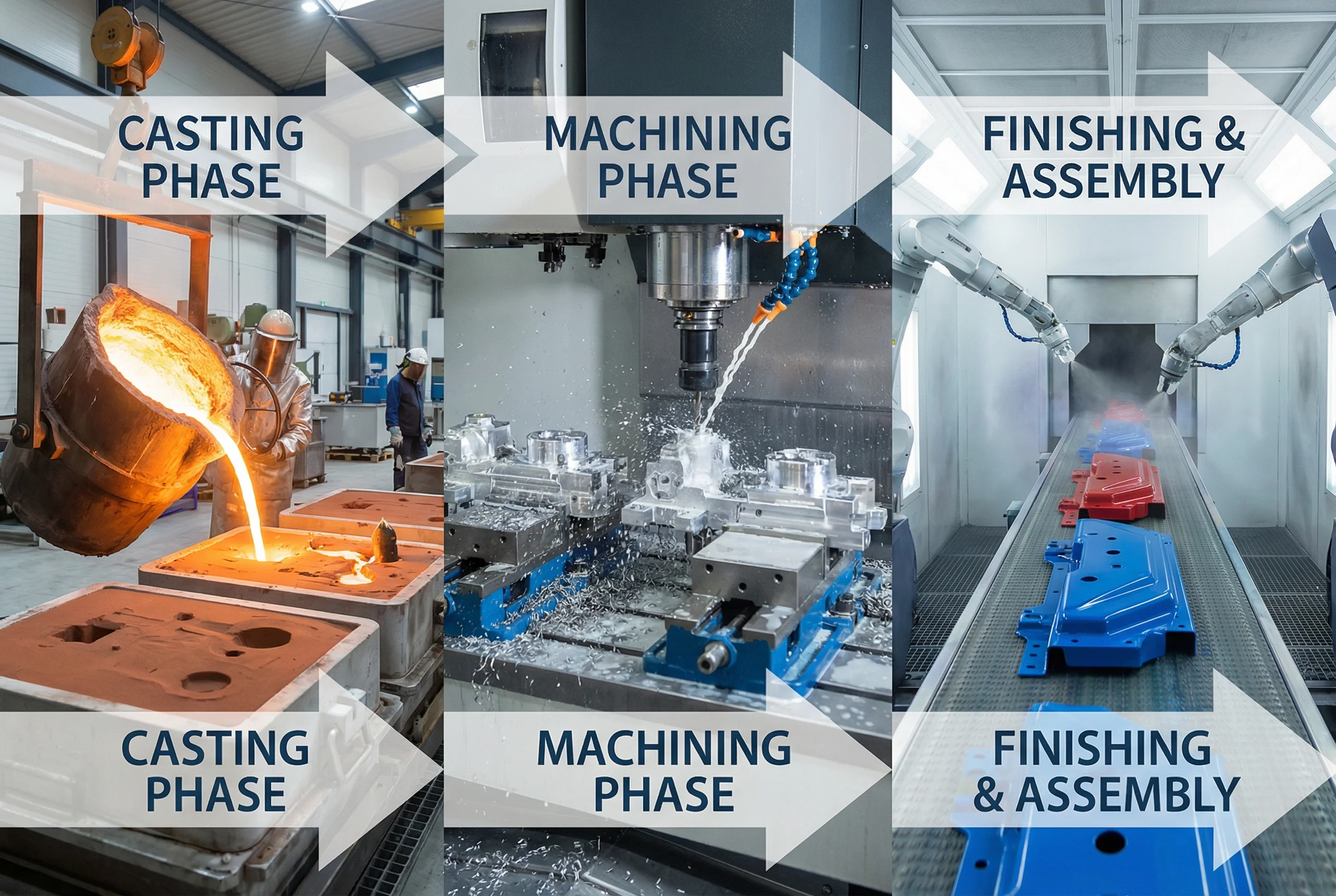

Four Divisions. One Integrated Solution.

Complete manufacturing capabilities under one roof

Since 1974

ROI Castings

Steel, Gray Iron, Ductile Iron & Lead Casting. No-bake, vacuum, and lost foam molding. Parts from 10 lbs to 15,000 lbs. Full painting line. ISO 9001:2015 | C-TPAT Certified.

IATF Certified

Stamptek

High-Volume Metal Stamping. 41 presses: 5 to 1,200 tons. Progressive, transfer, tandem & blanking. 8 TIG robotic welders. In-house tooling. IATF 16949:2016 certified.

Precision

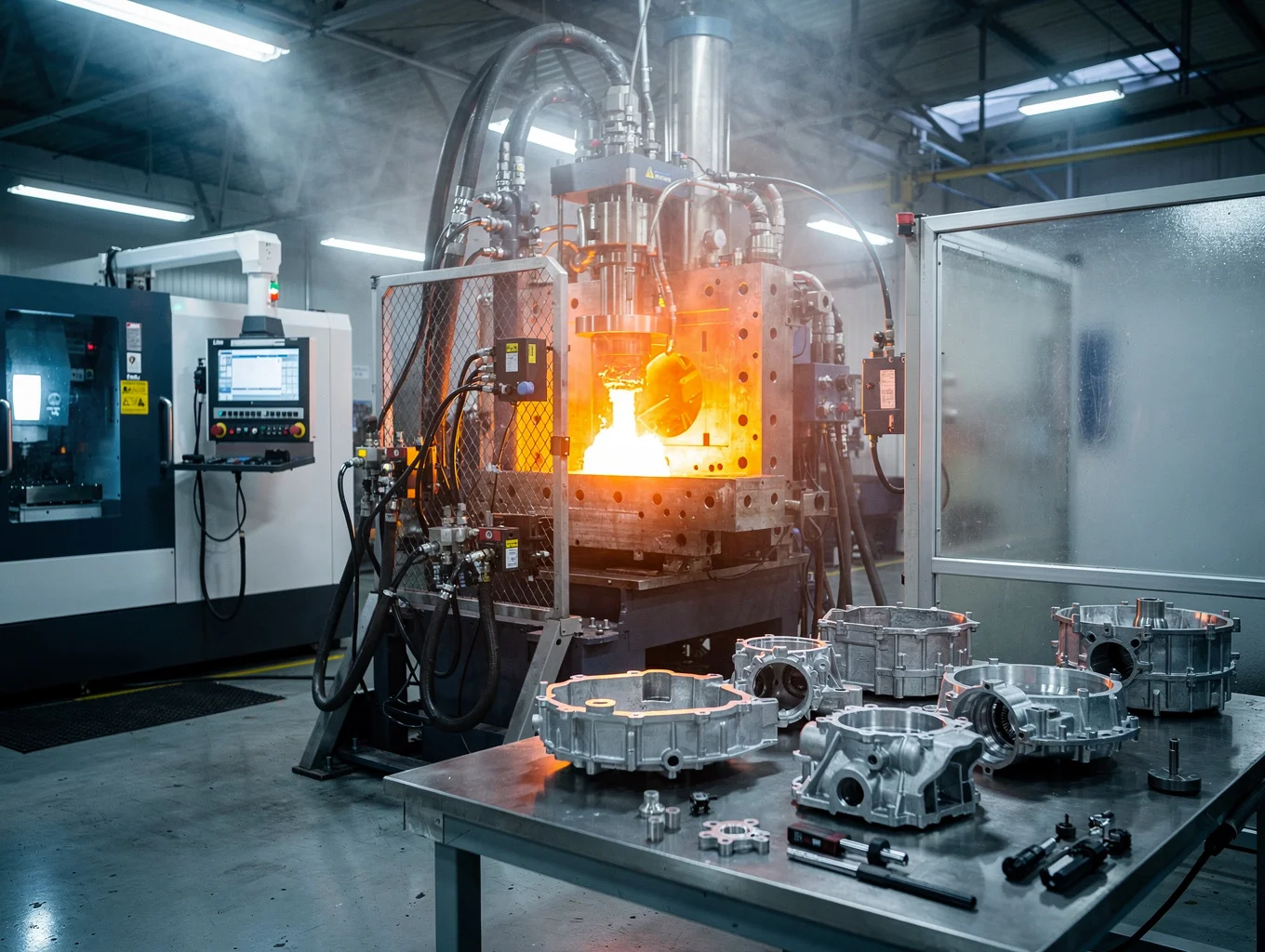

Rome Aluminum

High-Pressure Die Casting. HPM 600T & UBE 900T machines. In-house heat treatment up to 1200°C. Full CNC machining & finishing. Complex geometries, tight tolerances.

Quality Media

Advanced Abrasives

Steel Shot Blast Products. High-quality media for cleaning and finishing. Consistent particle size distribution. Extended media life for lower operating costs.

Why Multinationals Choose Us

What you need. What we deliver.

Reliable Delivery Performance

Our integrated operations and dedicated logistics team ensure your parts arrive when you need them. We track every order in real-time and proactively communicate any potential delays.

Complete Quality Assurance

Every part manufactured at Rome Holding carries complete traceability. From raw material to finished product, you know exactly what you're getting.

Responsive Partnership

Your dedicated account manager knows your business and responds within 4 hours. No getting bounced between departments or waiting days for answers.

Strategic Location Advantage

USMCA compliant manufacturing from Aguascalientes, Mexico. Competitive labor costs with North American quality standards. Just 10 hours to the US border.

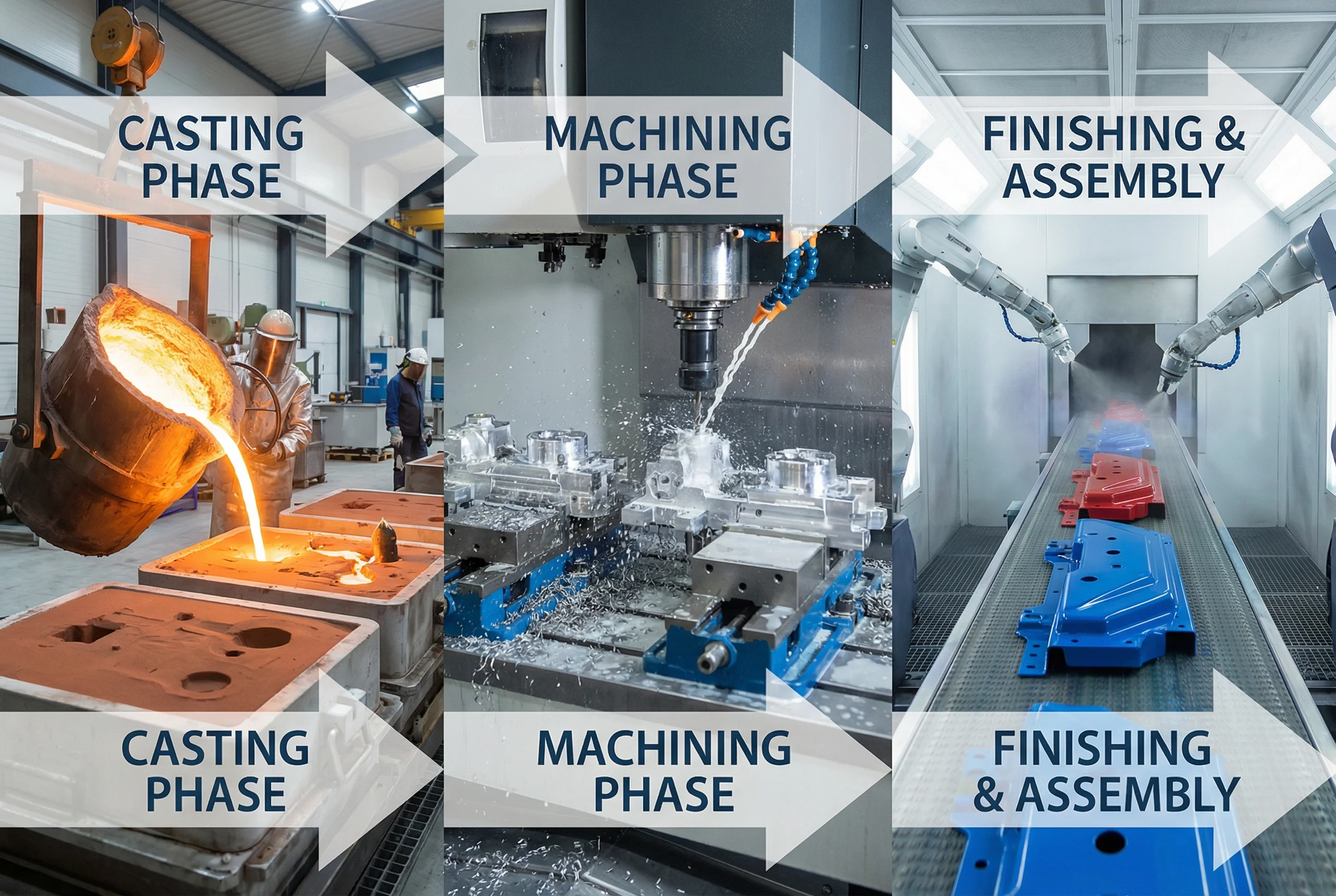

End-to-End Manufacturing

From raw material to finished assembly under one roof. No coordination headaches between multiple suppliers. One partner, complete accountability.

Scale With Confidence

Our facilities have the capacity to grow with your needs. Ramp up or down without penalty. From prototype quantities to high-volume production.

Reliable Delivery Performance

Our integrated operations and dedicated logistics team ensure your parts arrive when you need them. We track every order in real-time and proactively communicate any potential delays.

Complete Quality Assurance

Every part manufactured at Rome Holding carries complete traceability. From raw material to finished product, you know exactly what you're getting.

Responsive Partnership

Your dedicated account manager knows your business and responds within 4 hours. No getting bounced between departments or waiting days for answers.

Strategic Location Advantage

USMCA compliant manufacturing from Aguascalientes, Mexico. Competitive labor costs with North American quality standards. Just 10 hours to the US border.

End-to-End Manufacturing

From raw material to finished assembly under one roof. No coordination headaches between multiple suppliers. One partner, complete accountability.

Scale With Confidence

Our facilities have the capacity to grow with your needs. Ramp up or down without penalty. From prototype quantities to high-volume production.

Laboratory Capabilities

Quality Assurance — Built Into Every Step

State-of-the-art laboratory and testing capabilities ensure every part meets your specifications.

Our Location Advantage

Step 1

Send Your Requirements

Share your drawings, specs, and volume needs. We respond within 48 hours with a comprehensive review.

Ready to Eliminate Supply Chain Risk?

Get a quote in 48 hours. No commitment required.